Curtiss-Wright Corporation (NYSE:CW) today announced that it is ideally aligned to help drive the transition to electrical power currently underway across the Aerospace & Defense industry with new solutions and technologies from its Defense Solutions, Actuation, and Sensors divisions. Growing demand for solutions that deliver reduced size, weight, power and cost (SWaP-C) and enable zero emission initiatives, combined with the emergence of new applications – such as autonomous vehicles, swarming and loyal wingman drone fleets, and underwater unmanned vehicles (UUV) – is helping to accelerate the move away from fossil fuels and legacy hydro-mechanical system designs.

Curtiss-Wright is participating in the move to electrification across a broad range of air, land, and sea platforms and currently supplies a number of core technologies and services that span both the Aerospace and Industrial markets and are also transferable to Defense applications.

Drive Technology and Motion Control

Reflecting the turret drive stabilization market’s steady move toward electromechanical operation in recent years, at DSEI 2023 Curtiss-Wright will showcase its next-generation High-Voltage Turret Drive Stabilization System (HV TDSS). The HV TDDS converts 28V battery power up to 750V peak power for precision maneuvering of high-inertia loads on such platforms as large caliber turrets and main battle tank turret drive and stabilization systems. The innovative system provides short-burst high power without adding SWaP-C or the risk of damage to sensitive electronics. It’s ideal for applications such as high-speed motion control systems, mobile air defense, high-speed launchers for active protection systems, and mobile radar stations, cranes, trucks, and excavators. The HV TDDS is also well suited for use in naval weapon system applications on a wide variety of platforms, including warships.

The Benefits of Electro-Mechanical Actuation (EMA) Technology

Electro-mechanical actuation (EMA) technology delivers proven and compelling benefits and advantages, such as superior reliability and improved energy efficiency, over traditional hydraulic approaches for a wide range of aviation applications. Compared to hydraulic actuation, EMA delivers significant improvements for SWaP, with lighter and smaller alternatives that result in significant weight savings at the system level. In October 2017, Curtiss-Wright was first-to-market with a distributed rotary electromechanical spoiler and flap actuation system developed for Part 23 aircraft.

Curtiss-Wright is committed to being an industry leader in bringing the revolutionary advantages of electric actuation to flight, from fixed wing to rotorcraft, from general business jets to military platforms. Curtiss-Wright’s Actuation Division is a leading supplier of EMA systems for a wide range of defense aviation applications, including flight controls, engine controls, and landing gear. Of note, the division supports Eviation’s all-electric aircraft, the Alice, with a commercial-off-the-shelf (COTS) lightweight, plug-and-play primary flight control actuation EMA solution that reduces cost, schedule risk, and program risk. In addition, Curtiss-Wright’s Defense Solutions Division provides Eviation with its IADS flight test software for real-time and post-flight data visualization, analysis, and reporting.

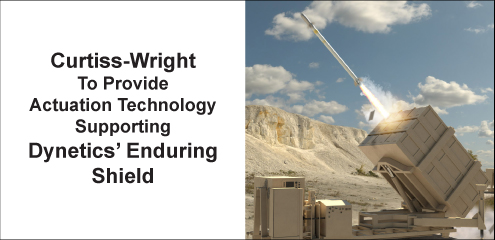

In February 2023, Curtiss-Wright announced that it had been selected by Dynetics, a Leidos company, to provide EMA actuation technology to support the new Enduring Shield platform to meet the U.S. Army’s cruise missile defense needs. Under the contract, Curtiss-Wright is providing EMA elevation and stabilization actuators for the mobile ground-based weapon system, which is designed to acquire, track, engage and defeat cruise missiles, rockets and unmanned aircraft system threats.

The Electric Path to Decarbonization of Military Flight

As requirements for electric solutions for military aviation are rapidly growing, Curtiss-Wright’s Actuation Division develops technology that contributes to the survivability of defense aircraft while improving their reliability. We are also seeing expanding use of uncrewed aircraft in the defense sector, a type of platform for which electric systems are highly relevant. In support of commercial aircraft and Advanced Air Mobility (AAM) markets, the division’s highly integrated electromechanical actuators are helping to increase flight efficiency and support decarbonization efforts. For example, to power the new generation of zero-emission/electric aircraft, Curtiss-Wright’s distributed flight control systems are being used where conventional hydraulic architectures are no longer an option.

The Actuation Division’s Exlar business is an industry-leading supplier of electrically powered stabilization and elevation solutions for demanding applications. Examples of military applications supported by Exlar include EMA to replace hydraulic and pneumatic technologies on missile defense systems, end-of-arm components for bomb disposal robots, lift actuation for high power microwave weapons and jet blast deflectors onboard naval platforms such as aircraft carriers.

Next Generation Airframes and Electrification

In 2022, Curtiss-Wright's Actuation Division announced that it was selected by Airbus UpNext to provide custom EMA technology for use on the eXtra performance WING demonstrator project which is focused on decarbonization and improved efficiency for next-generation aircraft. The project, which will explore active control technologies to improve wing performance, includes an intelligent wing tip, known as a semi-aeroeslastic hinge, which holds great potential for the reduction of CO2 emissions. Curtiss-Wright is providing Airbus UpNext with an actuation system for control of the semi-aeroelastic hinge on a scaled demonstrator aircraft. The demonstrator integrates the eXtra performance WING on a Cessna Citation VII business jet. The semi-aeroelastic hinge technology enables a more efficient wing design that improves aircraft fuel burn and reduces environmental impact. The demonstrator will improve and optimize wing aerodynamics and performance for future commercial aircraft, regardless of propulsion solution and aircraft configuration. Curtiss-Wright derived its design from electric actuator technology it developed for a recent business jet program as well as heritage concepts reaching as far back as the hinged-wing North American XB-70 supersonic bomber project of the 1960s.

In another example of how EMA is bringing innovative solutions to aviation, Curtiss-Wright’s Actuation Division, also in 2022, was selected by Airbus to provide rotary and linear actuators, alongside control and power electronics, to open, close, latch and lock the new A350F freighter aircraft’s Main Deck Cargo Door. Curtiss-Wright’s EMA design also includes a high-voltage DC architecture that minimizes weight, offers improved reliability over legacy systems, and incorporates health monitoring functions.

Sensors: Moving from Wire-Wrapped to Solid-State

Curtiss-Wright’s Sensors Division produces high-accuracy linear variable differential transformers (LVDT) and other position sensors, solenoids and valves that enable precise control of fuel metering and air management systems in aircraft gas turbine engines and contribute to reduced fuel burn. The division also supplies linear and rotary electro-mechanical actuators with integrated gearing/clutches/brakes/position sensing and actuation control electronics. The division’s ultra-high temperature sensing and control solutions are supporting the next generation of aircraft engine development programs with control solutions located close to the engine core to deliver even greater levels of fuel efficiency and lower emissions. Their solid-state sensor products provide electronics-based sensing technologies that deliver reduced size, mass and cost versus conventional inductive solutions, and support the growing need for lighter and ‘smarter’ sensors in markets such as AAM. In one recent example, the Sensors Division was selected to provide a new tailplane indication system for the upgrade of a leading training aircraft platform. The solution features contactless rotary hall effect sensors and microprocessor driven indicators that increase system service life from 400 flight hours to more than 80,000 flight hours. These rugged long-life programmable DC-output based contactless sensor solutions eliminate the need for modifications to the aircraft’s electronics, greatly reduce service intervals, and significantly increase the life of the tailplane indication system. The new electronic sensor design replaces legacy wire-wound sensors. This new generation of contactless sensors is smaller and lighter and has no moving parts, all of which makes them ideal for use in next generation Unmanned Aerial Systems (UAS) platforms.

Curtiss-Wright is proud to continue its legacy of innovation with new technologies and solutions that lead the way in the Electrification Revolution, bringing new capabilities to our warfighters.

For more information, please visit:

Defense Electronics Segment

CURTISS-WRIGHT DEFENSE SOLUTIONS DIVISION

Curtiss-Wright Drive Technologies (CWAT)

Location: Neuhausen and Rheinfall, Switzerland

https://www.curtisswrightds.com

Aerospace and Industrial Segment

CURTISS-WRIGHT ACTUATION DIVISION

Systems and components for Aerospace, Defense & Industrial Automation

Location: Shelby, NC

https://www.cw-actuation.com

CURTISS-WRIGHT SENSORS DIVISION

Flight critical components for aerospace

Locations: Gilbert, AZ (HQ) - Long Island, NY - Stratford, Ontario, Canada - Christchurch, UK - Nogales, Mexico

https://www.cw-sensors.com