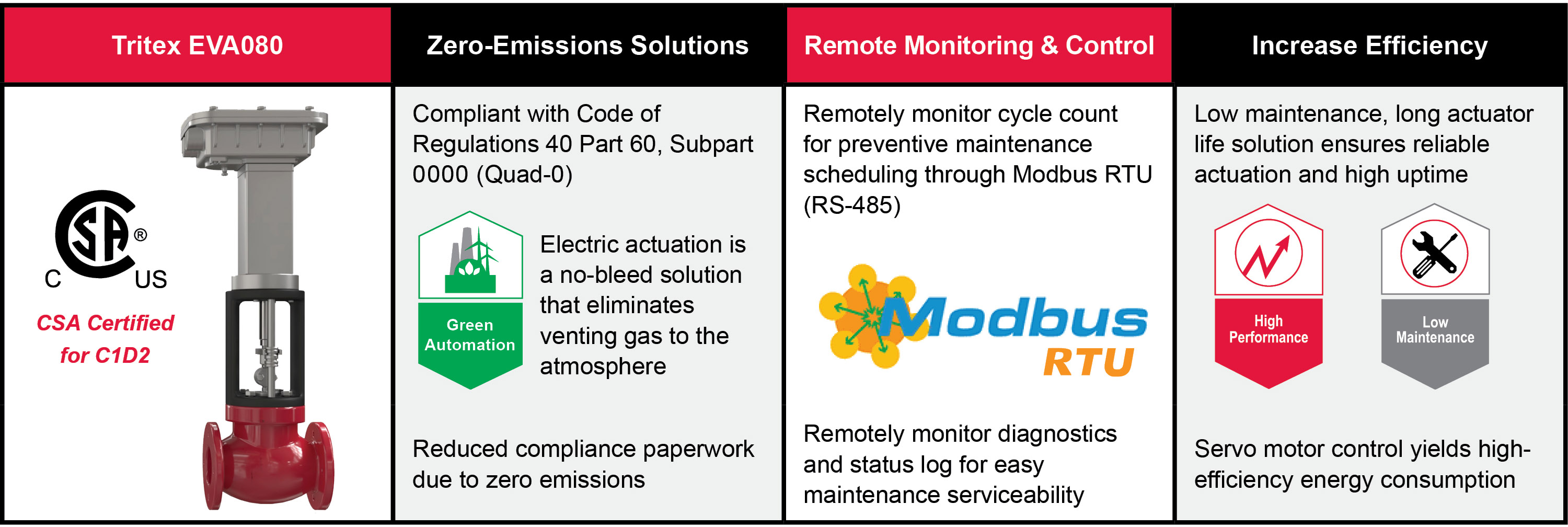

Flow Control - Our flow control actuators easily retrofit to existing control valves and provide accurate and precise modulating control. Designed for precision and long life, Exlar electric actuators for gate valves are well suited for harsh environments where dependability is necessary.

Choke Valves - On well sites, where proper pressure control is essential, electric actuators are now being used to effectively manage choke valve applications. The industry leading response time and greater stiffness of these actuators can’t be beat.

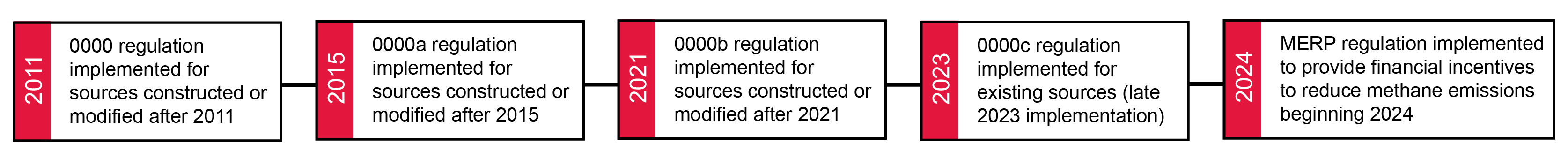

Pressure Control - Accurate, repeatable pressure control is vital to oil and gas pipelines. Our robust actuators outperform competition in Class 1 Division 2 applications in both northern and southern climates. We offer high performance solutions that meet today’s environmental standards.

Dump Valves - Intelligent electric valve actuators from Exlar® easily retrofit in place of traditional pneumatic diaphragm actuators on separator dump valves for simple on / off control. Those same actuators are also capable of precisely modulating the flow of product through the valve, offering control engineers new process capabilities not previously available.

Plunger Lift - Exlar® electric valve actuators offer a simple, maintenance free, robust, and reliable solution for plunger lift applications. Exlar actuators provide cleaner alternative to traditional pneumatic diaphragm valve actuation that is both networkable and programmable.

Chemical Injection - Roller screw electric actuators from Exlar® provide extreme precision for chemical injection pumps, minimizing waste and maximizing your bottom line. Designed for continuous duty operation, Exlar actuators maintain their precision over tens of millions of cycles making them ideal for chemical injection applications.