CW AWARDED CONTRACT FROM FEDERAL EQUIPMENT COMPANY

23 March 2021

CW AWARDED CONTRACT FROM FEDERAL EQUIPMENT COMPANY

Exlar’s field proven Commercial Off the Shelf (COTS) actuation products are used in a variety of industries and applications providing robust, reliable and energy efficient solutions.

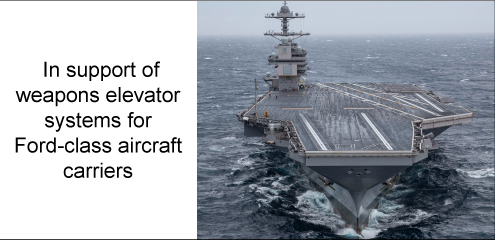

Shelby, NC – March 23, 2021 – Curtiss-Wright Actuation Division today announced that it has been awarded a contract to provide Exlar® Electro-Mechanical Actuators to Federal Equipment Company in support of their weapons elevator systems for the Ford-class aircraft carrier program. Exlar actuators are used in several other mission critical areas on the Ford-class carriers, including the Jet Blast Defector, Integrated Catapult Control Station, and LSO actuation systems.

Exlar’s field proven Commercial Off the Shelf (COTS) actuation products are used in a variety of industries and applications providing robust, reliable and energy efficient solutions. These COTS and Modified-COTS products and technologies are used in numerous naval and ground defense applications, as well as offering alternatives to fluid power options while providing lower total cost of ownership through energy efficiency, lower maintenance costs, and integration with automated control systems.

Federal Equipment Company (FEC) also uses the Exlar GSM Series integrated products as lock actuators for the weapons elevator systems they provide to the Ford carrier program on their CVN-78 and -79 ships. Phil Bowker, Curtiss-Wright Senior General Manager, Actuation Division stated, “We are proud to be able to continue to support both FEC, the US Navy, and its shipbuilder as the Navy modernizes its carrier fleet.”

Exlar is a business unit of Curtiss-Wright’s Actuation Division. For more information about Curtiss-Wright’s Exlar business, please visit https://www.cw-actuation.com/.

About Curtiss-Wright Corporation

Curtiss-Wright Corporation is a global innovative company that delivers highly engineered, critical function products and services to the commercial, industrial, defense and energy markets. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing reliable solutions through trusted customer relationships. The company employs approximately 8,200 people worldwide. For more information, visit www.curtisswright.com