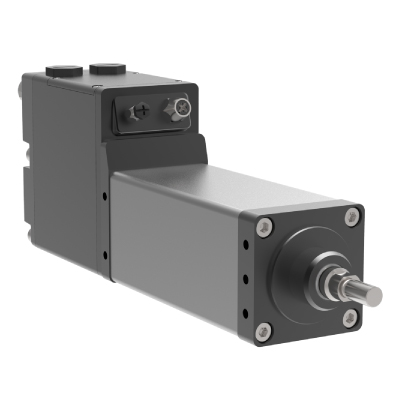

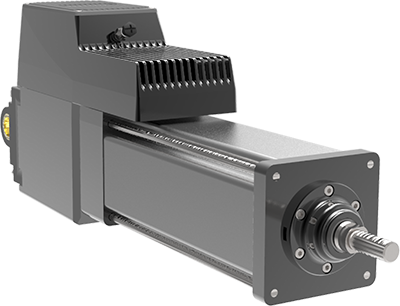

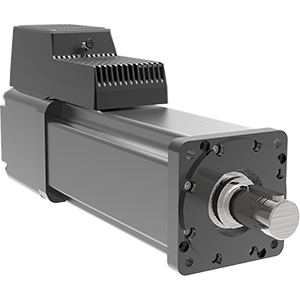

Intelligent Drive | Motor | Actuators

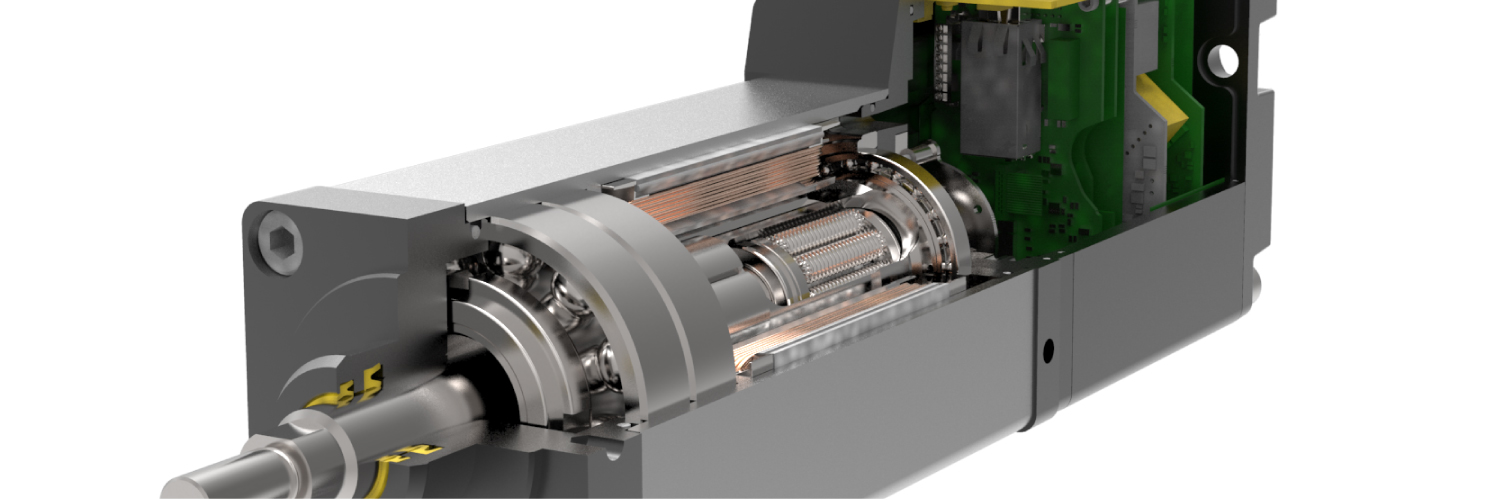

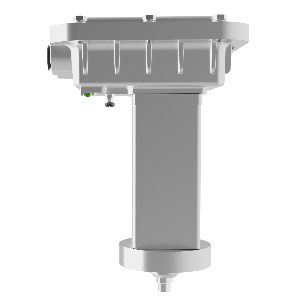

Tritex® intelligent programmable actuators are a decentralized solution that incorporates an on-board servo drive, industrial Ethernet communications, servo motor, and inverted roller screw actuator into a compact, power-dense package. These servo-controlled linear and rotary actuators offer a full range of options for almost any application.