Distribution portal

- Home

-

Industrial - Exlar®

- Exlar Products

- Universal Linear Actuators

- Integrated Motor | Actuators

- Intelligent Drive | Motor | Actuators

- Rotary Actuators

- Exlar Legacy Product Support

- Industries

- Automotive / EV Battery / Pressing

- Food & Beverage / Packaging

- Oil & Gas

- Plastics

- Forestry

- Entertainment / Simulation

- Other Industries

- Resources

- Returned Goods Authorization

- Exlar Product Overviews

- Exlar Product Manuals

- Brochures / Catalogs

- Case Studies

- Exlar Videos

- Actuator Technical Tips

- White Papers

- Online Tools

- Exact Sizing & Selection Tool

- Software & Downloads

- About Us

- About Exlar

- Rockwell Automation Support

- Terms & Conditions

- Careers

- Certifications

- Aerospace

- Ground & Naval Defense

- InfoCenter

- News & Events

- Contact Us

Exlar Products

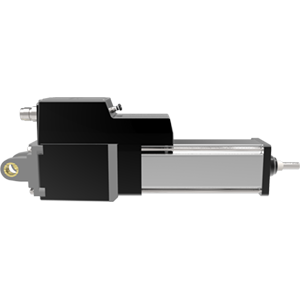

Universal Linear Actuators

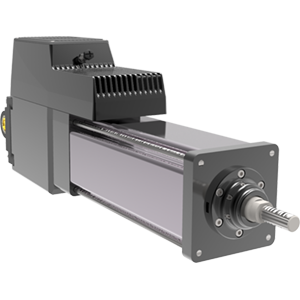

Integrated Motor | Actuators

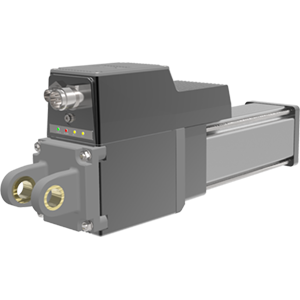

Intelligent Drive | Motor | Actuators

Rotary Actuators

Exlar Legacy Product Support

Industries

Automotive / EV Battery / Pressing

Food & Beverage / Packaging

Oil & Gas

Plastics

Forestry

Entertainment / Simulation

Other Industries