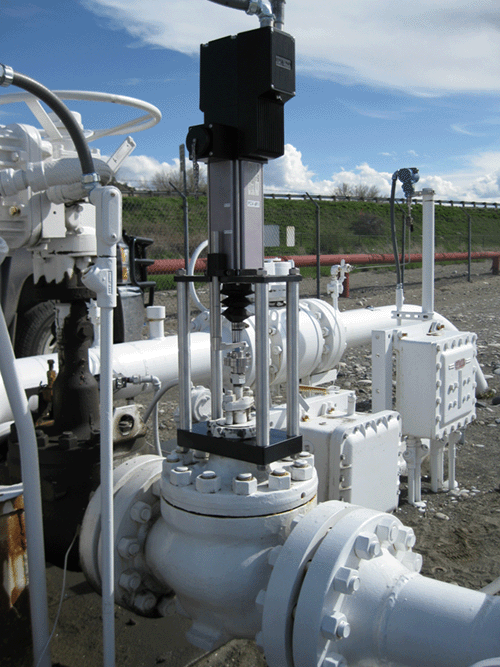

Exlar Electromechanical Actuators for Oil & Gas

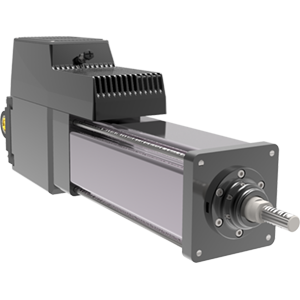

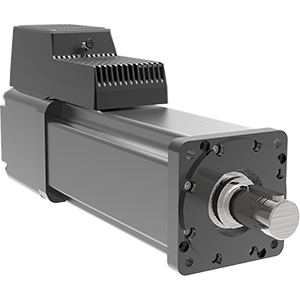

Exlar offers reliable roller screw driven electromechanical actuators configured to meet the harsh demands of outdoor environments all over the world in oil & gas process control applications.

Electromechanical actuators are an ideal replacement for fluid powered actuation for those OEM’s looking to improve overall equipment effectiveness (OEE) with advantages in these areas:

- Reliable to eliminate failures and downtime

- Power dense to eliminate space needed

- Accurate and repeatable to quickly adjust flow with no overshoot

- Hazardous rated

- Electric to eliminate the need for pumps, compressors, hoses

- Closed loop to offer constant and accurate feedback of valve stem position

- Easy to configure/install through our process control specific software

Exlar electromechanical linear actuators transmit torque from the motor to force at the rod end using precision ground roller screws, these screws can provide advantages over other electromechanical linear technologies in these areas:

- High rigidity - increases accuracy

- Life - up to 15x longer than ball screws, even longer when compared to other screw technologies

- Able to withstand high shock and vibration

- Able to be taken apart for regreasing in the field

***Check out our latest in white papers and success stories below***

Eliminate Methane Emissions with Exlar Electric Actuators

For oil & gas production companies, methane emissions via pneumatic venting has become a major cost issue from lost gas revenue, potential fines, EPA reporting requirements and strict area classifications. Remote sites often use natural gas-powered pneumatic controllers for process control. The controllers are designed to continuously bleed natural gas resulting in significant methane emissions to the atmosphere. New studies are showing emissions from these low bleed pneumatic actuators are higher than original EPA national emission projections, which could impact the original regulations. In addition, the use of any device that vents methane in an enclosed area forces the area to be classified as Class 1 Division1 explosion proof, adding to the cost of equipment.

A solution to these venting problems is the use of an electric actuator in place of pneumatics, completely eliminating the venting of methane. This regains the lost vented gas revenue, reduces the need for emission monitoring and could allow for re-classification for many enclosed separator batteries to Class 1 Division 2 status.

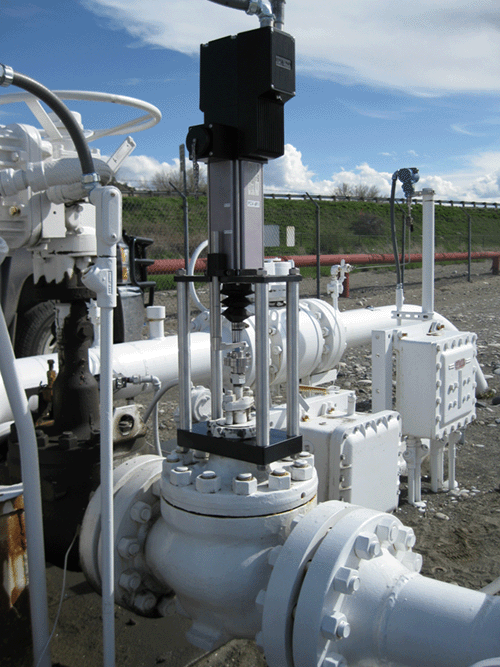

Flow Control - Exlar® electric valve actuators provide accurate and precise modulating flow control. Easily retrofit-able to existing control valves, Exlar valve actuators are designed for precision and long life, and are well suited for harsh environments where dependability is a necessary.

Choke Valves - On well sites, where proper pressure control is essential, electric actuators are now being used to effectively manage choke valve applications. The industry leading response time and greater stiffness of these actuators can’t be beat.

Pressure Control - Accurate, repeatable pressure control is vital to oil and gas pipelines. Our robust actuators outperform competition in Class 1 Division 2 applications in both northern and southern climates. We offer high performance solutions that meet today’s environmental standards.

Dump Valves - Intelligent electric valve actuators from Exlar® easily retrofit in place of traditional pneumatic diaphragm actuators on separator dump valves for simple on / off control. Those same actuators are also capable of precisely modulating the flow of product through the valve, offering control engineers new process capabilities not previously available.

Plunger Life - Exlar® electric valve actuators offer a simple, maintenance free, robust, and reliable solution for plunger lift applications. Exlar actuators provide cleaner alternative to traditional pneumatic diaphragm valve actuation that is both networkable and programmable.

Chemical Injection - Roller screw electric actuators from Exlar® provide extreme precision for chemical injection pumps, minimizing waste and maximizing your bottom line. Designed for continuous duty operation, Exlar actuators maintain their precision over tens of millions of cycles making them ideal for chemical injection applications.