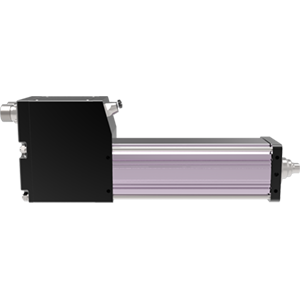

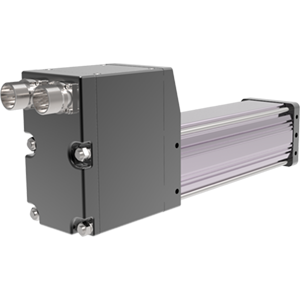

Compact intelligent DC linear actuator, innovative and precise

The Tritex II DC-powered unit houses a servo drive, digital positioner, and electric actuator all in one compact package. These advanced linear actuator cylinders offer the highest power density and smallest footprint servo drive devices on the market. Their small size and innovative design make it easy to incorporate a fully electronic solution in the space of your existing hydraulic or pneumatic cylinder. Tritex II Series actuators integrate a DC-powered servo drive, digital position controller, brushless motor, and linear actuator in a compact, sealed package. Now you can precisely control motion and solve your application requirements with a single, intelligent DC-powered actuator.

DC Linear Actuator Benefits

Power, Performance, and Reliability

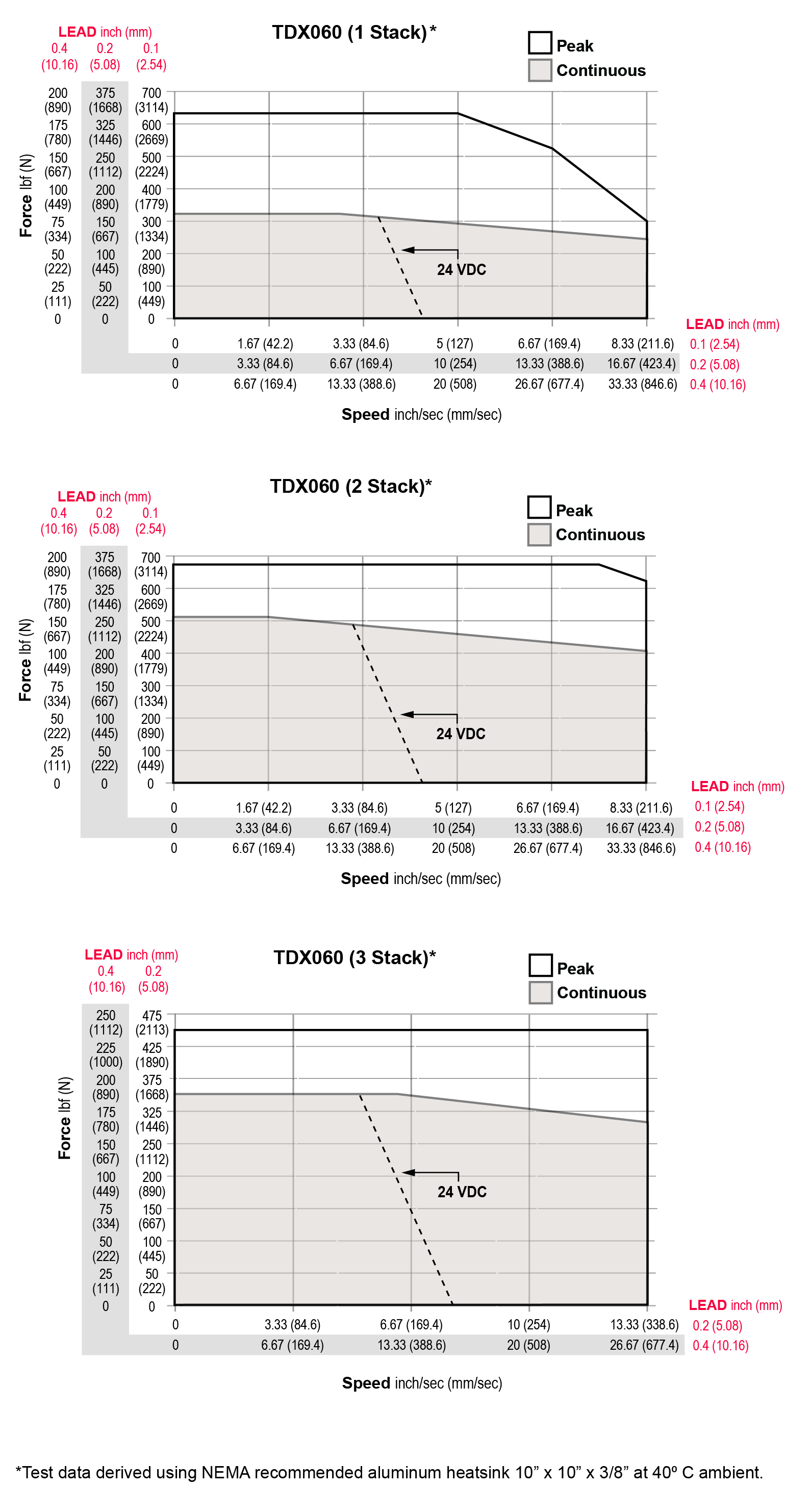

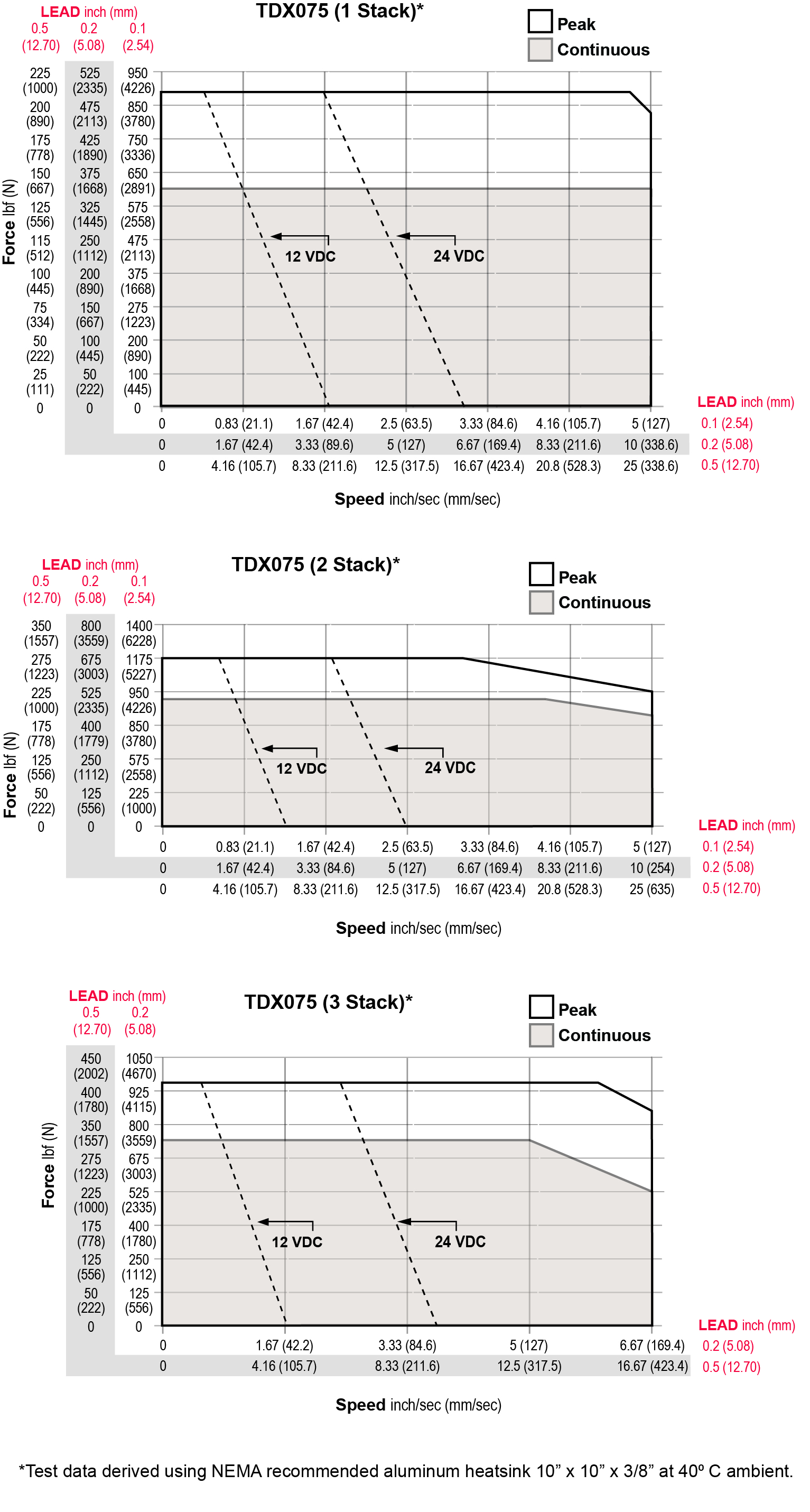

With continuous force to 872 lbf (3879 kN), peak force up to 1190 lbf (5293 kN) and maximum speed to 33 in/s (800 mm/s), the Tritex II DC linear actuators offer a robust and superior solution. The DC power electronics provide maximum reliability over a wide range of ambient temperatures (-40 to +65 degrees Celsius). With their 750W servo amplifier and roller screw design, these actuators are top performers. Standard features such as the analog following for position, compound moves, chaining, and individual force/torque control put you in the driver seat.

Compact Package and Low Operating Costs

Tritex II is a robust solution with a small form factor that consistently delivers exceptional reliability and performance. Since the electronics and mechanics are housed in a single, sealed package, space requirements and wiring are minimized. Also, the integrated design eliminates labor costs associated with panel mounting and wiring. At the same time, it eliminates costly and high-maintenance servo cables while resolving troublesome signal strength issues.

Other Advantages

- Maximum power, precision, and speed in a compact package

- Superior replacement for pneumatic and hydraulic cylinders

- IP66S rated for use in harsh environments

- Roller screw design eliminates the need for inferior ACME and ball screw solutions

- Programmable software enables automated sequencing

- Multiple feedback types to best suit your application

- Seamless integration with your control architecture and processes

- Engineered for closed-loop servo systems

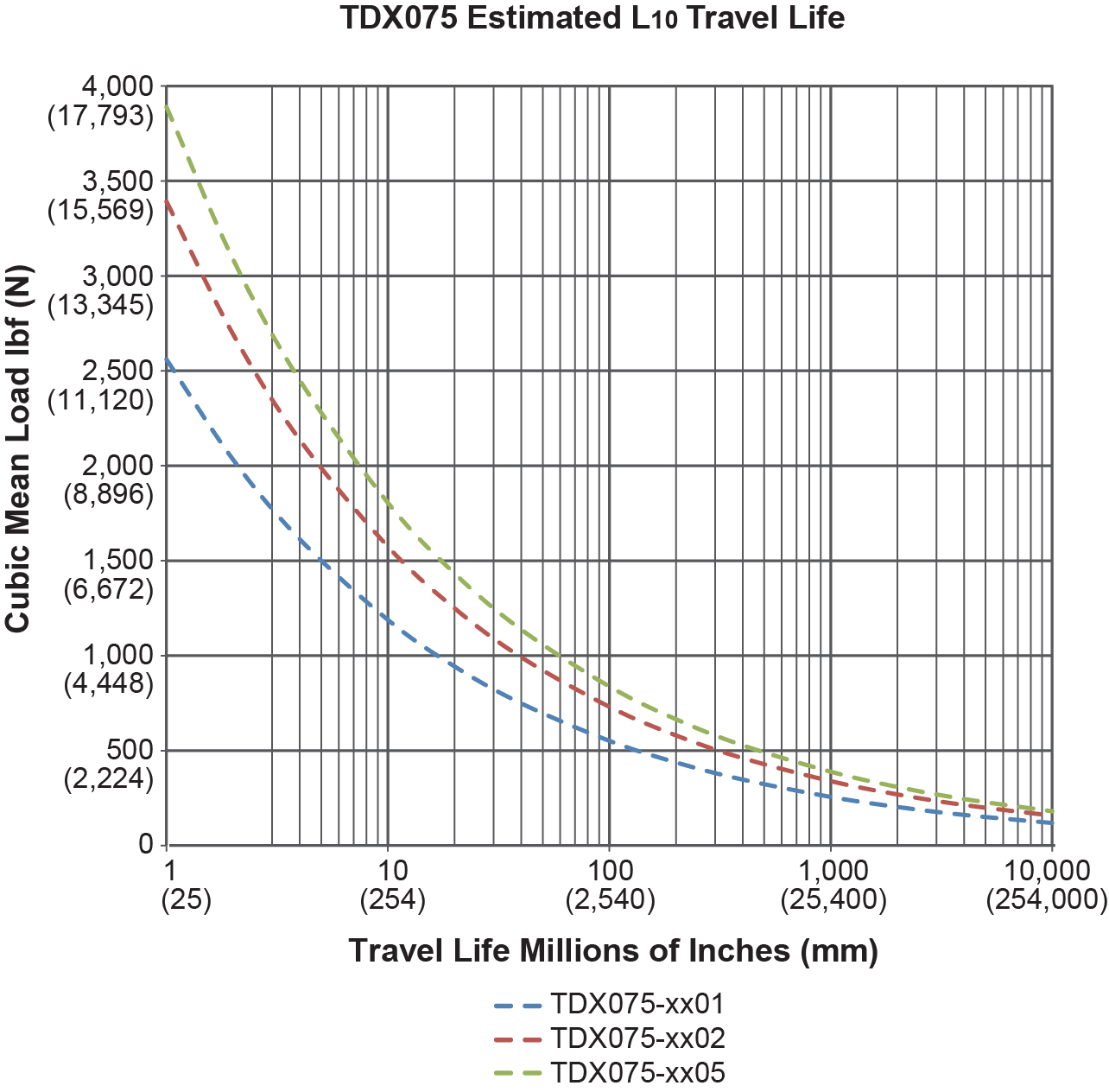

- 100% duty cycle for hundreds of millions of strokes

- Sealed housing for extended life and reduced maintenance

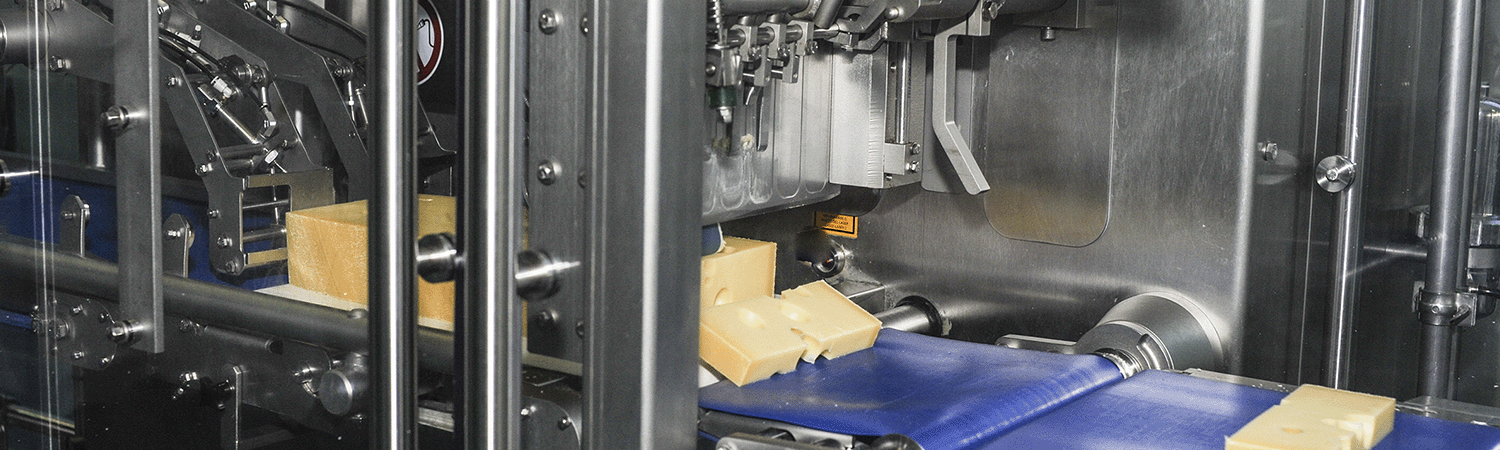

DC Linear Applications Perfect for the Tritex TDX

Electric actuators are used in various medical applications, ranging from simple applications to more complex applications that require more significant force, speed, and control from the actuator. An example of a standard, low-end performance actuator application is a simple hospital bed adjustment. The electric actuator applies minimal force to adjust the bed height up or down to accommodate operator and patient use. In addition to simple applications, electric actuators also are used for high-performance applications such as volumetric filling and fluid dispensing, which require higher forces and high cycle rates. For example, consider an application in which the electric actuator is used as a piston pump to inject fluid into the patient. Before patients receive treatments, operations, medical imaging tests, dyes, or other media are injected to help detect abnormalities. To successfully inject the media, the electric actuator must be compact, produce a high force to create sufficient pressure, and maintain accurate velocity for a consistent injection rate.

If the actuator does not produce enough force, the injection volume will not be correct, resulting in potential harm to the patient and possible failure of the subsequent test. The combination of elevated forces and velocity control produces better results for the doctors and an easier procedure for the patients. Other higher performance applications include laser positioning, which requires high precision, and ultrasonic welding, which requires stability, accurate position, and velocity control. Precision position, velocity control, and force sensing allow electric actuators to perform these applications effectively.

Integration is key

With enhanced features, electric actuators have become a primary option for medical applications. Today, electric actuators offer more power, force, load capabilities, and control than earlier versions, with other advancements including smaller size and integration of power and control components. With advances in technology, electric actuators can deliver higher forces, with load ratings to 100,000 lbs. and above. In meeting requirements for applications requiring high-load capacities, electric actuators still offer position and velocity control, including high-capacity presses and injection molding for medical products. Many electric actuators now integrate the motor and linear actuator into one package, reducing the overall size of the actuator. Instead of combining the size of the motor and actuator, the latest versions feature a compact size of only the motor. The smaller footprint allows them to be designed into compact medical equipment, providing the manufacturer with advantages offered by a more compact product.

Ergonomics and safety issues can also be reduced through the smaller size. In addition to a compact design, electric actuators now offer electric controls and power circuitry integrated within the actuator. Earlier versions require separately mounted controls and power amplifiers. Now, the actuator, drive, and control are completely integrated into one piece of equipment, eliminating the need for additional power supplies, separate power amplifiers, and expensive cables. This allows the manufacturer to distribute the entire motion system within their mobile medical device and not be tethered to a stationary electrical cabinet.

Electric actuators also produce less noise than their fluid-power counterparts, resulting in a better experience and smoother operation for the doctors and patients. Since the equipment is often located close to the patient, the equipment must operate quietly to reduce patient anxiety levels.

Looking ahead

Electric actuator advancements are changing how medical equipment designers view equipment designs. Many medical institutions are now demanding more compact sizes and more power. Integrating all of the components of a motion system within the actuator package is only the first step to the future design of electric actuators. As technology advances, designers will continue to expand electric actuators capabilities, delivering more force, speed, and control in a single, compact package.